Machine shops are essential to industries across America. CNC machining businesses specialize in the fabrication of parts, and the maintenance of metal, plastic and glass equipment. CNC machine businesses offer a variety of services based on equipment and training.

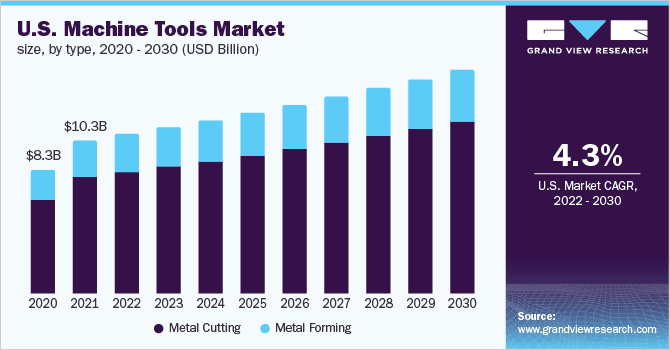

The CNC machine shop industry may see a decline in 2023. Still, Statistica suggests the market will hold a value of $27.4 billion by next year. Grand View Research predicts a CAGR of 4.3% between 2022 and 2030. If you’re thinking of starting a CNC machine shop, the time may be right.

Starting a new business is stressful. It requires a thorough and accurate business plan, including relevant market research, chosen services, pricing, and more. Throughout this guide, we’ll walk you through the ins and outs of starting your own machine shop.

1. Conduct CNC Machine Shop Business Market Research

Market research is the first step in the process of starting any new company. As a machine shop owner, you need to know what you need to get started, what competitors are offering, and who your customers are.

There are two ways to collect this information, primary research, and secondary research.

Primary research is the act of collecting data for yourself. This first-person research includes polling local businesses for computer numerical control machining needs and visiting competing shops in town.

Secondary research is available data collected by others and made accessible to you. This includes things like government website information, industry statistics, and online reviews of competitors left by local customers.

Some of the information you should look at collecting for your shop include:

- Target customer demographics

- Number of competing shops in the area

- Services offered by most CNC machining businesses tin the area

- Top industries in town potentially requiring machining services

- Top machining services

- Current prices in the market

You may also want to look at local businesses indirectly related to the machining industry. Businesses you could partner with, rather be in direct competition with.

Choosing the Right Services for Your Shop

Machine shops come in all shapes and sizes, catering to a variety of industries. Choosing the right services for your shop is important. Your market research will help you determine the most lucrative services for local business owners in your area. Some of the services most commonly offered by machine shops in the U.S. include:

- Milling (4-axis CNC milling and precision milling)

- Heat sink manufacturing

- Assembling (Hardware, bearings, sub-assembly match machining, bushings, etc.)

- Lathing

- Welding

- CNC turning

As a CNC machinist, you should also decide on the materials you’ll work with so you have the right tools on hand. Common materials are:

- Alloy

- Stainless steel

- Castings

- Aluminum

- Titanium

- Plastic

- Glass

- Wood

CNC machining businesses serve business owners in industries such as medical, aerospace, military, and construction.

2. Analyze the Competition

According to the Bureau of Labor Statistics, there were 254,090 employed in the machine shop industry as of 2021. Knowing your competition within your field of machining is important to the success of your new business.

Most of the competition you’ll come across as a machine shop is local (Unless you partner with, or obtain a contract from a large company in another state).

Some of the ways to analyze competitors include:

- Visiting other machine shops in person

- Asking businesses how their experiences have been with local machine shops

- Reading online reviews

- Visiting competitor websites

As you investigate the competition look at prices, services offered, and look for gaps you can fill within the industry.

There are plenty of shops in every state across the country. To find local competitors try searching with a search phrase like, “Machine shops in,” and add your city and state to the end of the phrase.

While most of your competition is local, it helps to look at national shops as well. Here are some of the major players within the machine shop industry.

Avanti Engineering Inc.

Avanti claims to be the “#1 screw machine products manufacturer in the U.S.” The company specializes in high volume machining, CNC machining, and screw machine products. They work with steel, aluminum, brass, stainless steel, and plastic.

Machinery Maintenance Inc.

Machinery Maintenance is based in Illinois. The shop is open 24/7 and offers services such as gearbox repair and rebuilding, boring and bushing, field welding, CNC machining classes, and quality control, and industrial pump repair, among others.

Xometry

Xometry is considered one of the top suppliers of machined products in the country. They offer custom online CNC services including turning, milling, metal sheet fabrication, die casting, and more. Xometry also partners with machine shops to supply raw materials and other resources, as well as jobs.

3. Understand the Costs of Starting a Machine Shop Business

As you learn to start your own machine shop you’ll notice some obvious and not-so-obvious costs involved. There are initial startup fees and ongoing costs to consider. Everything from registering your business to buying the equipment and materials needed to provide customer services is an investment.

Here, we’ll talk about some of the costs you’ll encounter and why they fluctuate.

What Does It Cost to Start a Machine Shop Business?

Initial startup costs vary depending on the size of your shop and the services you offer. The biggest costs within this industry are equipment related. A single machine, such as a milling machine can cost anywhere between $5,000 and $5,000 depending on the size, make, and model. Most shops start with a few different CNC machines.

Some of the main expenses you’ll encounter outside of equipment include:

- POS system

- Legal fees

- Website domain, design, and upkeep

- Employee pay and training

- Accounting

- Permits and licenses

- Marketing

- Administrative supplies

- Machining materials

Between equipment, leases, business registration, and other expenses, you could be looking at spending anywhere between $100,000 and $500,000 to start a successful shop in the U.S.

Business Equipment/Materials

Equipment in your machine shop will be the majority of your startup costs. CNC machines also need to be maintained and repaired, transforming your equipment into an ongoing cost as well.

Some of the equipment you’ll need to start your own shop includes:

- Milling machine: $5,000 to $5,000

- Lathe machine: $1,000 to $25,000

- Boring bars: $40 to $1,000

- Shapers:$600 to $3,000

- Planers: $500 to $10,000

- Grinding machine: $800 to $20,000

You’ll also need to invest in a design computer, software, hardware, and materials for fabrication. Some places to buy equipment for your own shop include Glen Mills and Penn Tool Co.

Cost of Renting or Leasing a Location

A commercial or industrial space for your shop will likely lease by the square foot. If the realtor is asking for $24 per square foot on a 1,000-square-foot building, you’ll pay roughly $24,000 a year to lease the place.

Commercial leases cost more in city centers, and near large populations. You may also pay more for new buildings.

Business Formation

To form a business you must first register with the Small Business Administration. Registering your business name and obtaining all necessary licenses and permits should cost between $300 and $800.

Business Insurance

Insurance is important for all businesses. Especially businesses where heavy machinery is being operated. High-risk workplaces should protect themselves, their staff, and customers with high-end insurance plans. Most machine shops invest in general liability insurance as a minimum level of insurance coverage.

Utilities

Utilities are a big cost for CNC machining businesses. Running electric machines regularly increases the electric bill from standard commercial property usage. Common utilities include:

- Electricity

- Water

- Heat

- Internet

- Phone

Most business owners should plan to spend roughly 4% of business expenses on utilities.

What Are the Ongoing Costs of a Machine Shop Business?

Ongoing costs are fees you pay continuously over the life of your business. Anything you need to replenish or make payments on falls into this category. Some of the common ongoing costs for a CNC machining business are:

- Lease payments

- Utilities

- Insurance

- Employee wages

- Materials and inventory

- Equipment maintenance costs

- Fuel for commercial vehicles

- POS fees

- Administrative supplies

Paying for repairs and parts of your machines is another ongoing cost. Having regular maintenance should extend the life and minimize the need for these repairs.

4. Form a Legal Business Entity

Your business name isn’t the only registration necessary when starting a CNC machining business. You also need to form a legal business entity. There are four main types of business formations. These are limited liability corporations (LLCs), sole proprietorships, partnerships, and corporations.

Limited Liability Corporation (LLC)

LLC formations are often the preferred choice of entity formation for small businesses. It gives you power over your company while maintaining a wall of separation between personal and business assets.

If something happens to your business, only business finances are used to pay for liability, legal, or medical financial repercussions.

Sole Proprietorship

For a single business owner or a married couple who own a business together, a sole proprietorship formation is an option. Sole proprietorships put you in the driver’s seat for your company. You get sole decision-making rights, but you also leave your personal assets at risk.

A sole proprietorship doesn’t separate personal and business assets like an LLC. If your machine shop business goes bankrupt, lenders will come for your personal assets.

Partnership

If a business is owned by multiple people, a partnership is a good option for families running a business together. Partnerships work the same as sole proprietorships, except ownership and decision making is split among the members.

Similar to a sole proprietorship, partnerships also don’t separate personal and private assets. If your machine shop damages parts for a client and legal action ensues, your savings could be at risk.

Corporation

The largest and most complex business entity is a corporation. Corporation formations protect your personal assets, but they’re difficult to apply for. There’s a lot of paperwork involved, and the process is more costly than any other business entity formation.

5. Register Your Business for Taxes

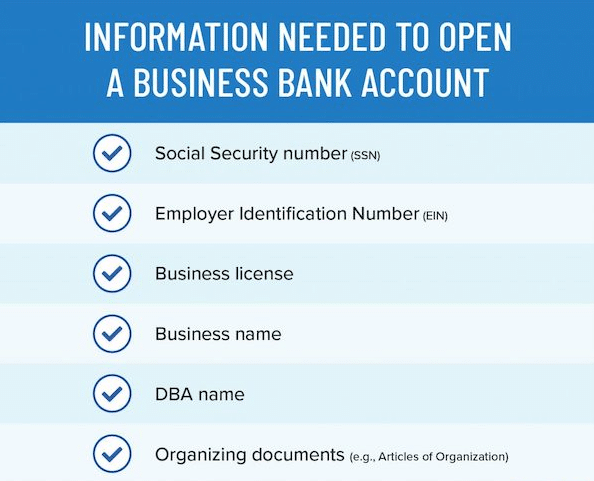

Paying taxes is part of every U.S. business. To pay taxes your company must first register an employee identification number (EIN). EINs are also referred to as federal tax IDs because they’re used to file annual taxes.

Your business needs an EIN to:

- Pay employees

- Open a business bank account

- File taxes

- Apply for a business credit card

Get your EIN through the U.S. Small Business Administration.

6. Setup Accounting for Success

Machine shops have many moving parts and employees to manage. Having accounting procedures in place helps organize incoming and outgoing money, manage inventory, remember client orders and service prices, and more.

As a small business, there are many options for bookkeeping and accounting. Some of the common recommendations for CNC machining businesses include the following.

Accounting Software

Automating bookkeeping processes through accounting software saves time and money. One of the best resources for this is called QuickBooks. QuickBooks software is designed with customizable features and tools to suit any business type. It also comes in different packages for varying budgets.

Some of the features of QuickBooks include:

- Inventory control

- Invoicing

- Bill and payroll management

- Job costing

- Cashflow

QuickBooks is designed for small to mid-sized companies. It’s the perfect resource for a new business.

Find an Accountant

Even the best business accounting software needs help at tax season. Working with a certified accountant ensures all paperwork is filed correctly and nothing gets missed.

An experienced accountant can charge up to $400 an hour.

Get a Business Bank Account

According to The Small Business Tax Workshop by the IRS, opening a business bank account is a smart step for small businesses. There are many factors to consider when organizing finances. A business bank account makes it easier to monitor earnings and spending.

Opening a business bank account requires you to legally register your company name and EIN, and form an entity.

Separating personal and professional finances minimizes the risk of fraudulent spending. It keeps business owners accountable and creates an accurate report for the IRS.

Apply for a Business Credit Card

Like a business bank account, a credit card for CNC machining business purchases separates personal and professional money. Business cards also get a variety of benefits personal cards don’t see. Higher travel mile and cash back rewards and lower APR are a few advantages.

7. Obtain Business Licenses and Permits

Running a small CNC machining business requires certain permits depending on the city and state you’re in. There are no set federal license regulations for machine shops. Check with the U.S. Small Business Administration before opening shop to be sure you’re in the clear.

For local permits, check with your local government and visit the SBA’s website.

8. Get Business Insurance

Machine shops are filled with potential peril. Insuring your business protects you against financial hardship if legal or liability issues arise. Machine shop owners have a wide range of product types to choose from. The most common are general liability, commercial/industrial property, and commercial vehicle.

General liability insurance covers damage to people and/or their property caused by services or products of your machine shop. Rates vary depending on the size of the company, risks involved in running the company, and past claims.

For $1 million in protection, you could pay anywhere between $300 and $1,500 a year.

9. Create an Office Space

Machine shop businesses involve a lot of manual and mechanical labor. That doesn’t reduce the need for administrative tasks. All businesses need time to organize finances, schedule employees, and complete paperwork.

Some shops have the benefit of an on-site office. This is a room dedicated to office work, and separate from the CNC machining business noise. If you don’t have an office in your shop, there are a few options.

Home Office

Many small business owners in the U.S. choose a home office for administrative duties. If your CNC machining business doesn’t have an office on-site, this is an affordable option to create one.

Home offices come with tax benefits. The IRS allows deductions of up to $1,500 per year. You can deduct individual expenses, including utilities, mortgage costs, and even gas money. Or, deduct $5 per square foot up to 300 square feet.

CoWorking Office

A coworking office is just as the name suggests. An office shared by workers. Think of it a little like a vacation timeshare. It’s leased by multiple people who share the cost and alternate use of the space. This is a great solution for business owners looking for an office without a lengthy commitment.

A great resource for coworking office spaces is WeWork. WeWork has options for every budget and work style. Choose from private, semi-private, and shared offices.

Commercial Building Office

The most expensive option for an office is leasing through a commercial office building. Commercial offices, like other commercial properties rent by the square foot. While they hold a lot of pomp and prestige, they may not be the best fit for a new small business owner.

10. Source Your Equipment

Starting a new machine shop comes with many expenses. Finding the best places to source equipment is a huge advantage. Equipment needs to be affordable, but also reliable. Here are some of your options.

Buy New

Machine shop employees rely on the tools and equipment at their disposal. Without reliable equipment, it’s tough to create high-quality products and repairs. Buying new ensures your equipment is in tip-top shape and ready to take on the task it was made for.

Some of the top places to find new machining tools and materials are Grainger and KBC Tools and Machinery.

Buy Used

Used equipment isn’t as desirable as the new stuff, but if vetted, it can be just as durable. Be careful to thoroughly inspect equipment and ask for proof of sale, age, and maintenance on large expensive items. Some places to buy used include Facebook Marketplace and Craigslist. You can also find used machine shop equipment through Bid-On-Equipment.

11. Establish Your Brand

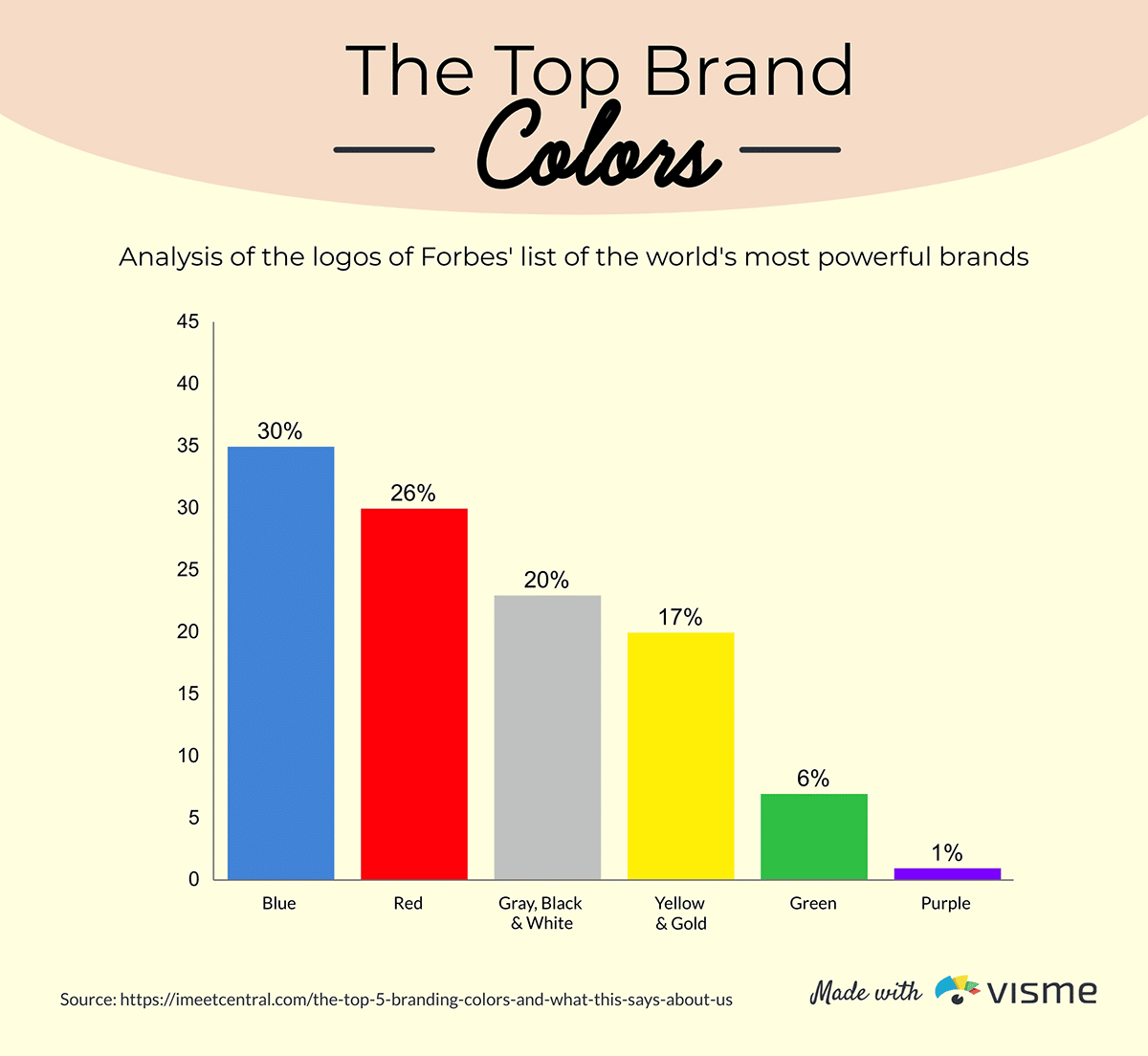

Branding your business defines it within the machine shop industry. It helps locals understand what your business does and why they should choose it over other machine shops in town. Everything from the colors in your logo to the design of your website impacts branding.

There are several ways to begin branding your business. Here are a few ways to get started.

Get a Business Phone Number

A business phone number is yet another way to separate the personal and professional. It’s a beneficial investment because:

- It organizes client phone numbers

- Creates a singular mode of contact for your machine shop

- Provides a sense of authority within your industry

There are plenty of business line options through major phone companies like AT&T. If you want something affordable and outside of the box, try Google Voice. It works from any digital tool including phones, laptops, adn tablets. And you can start a business line for as low as $10 a month.

Create a Logo & Brand Assets

Your logo makes your business memorable and unique. Think about the differentiation between similar big brands like Coke and Pepsi. We all know the logos, the colors used in the logos, and even the font type. Your logo helps customers set you apart from local competitors.

Try Looka for a simplified logo design experience. The platform uses AI to design a logo based on your tastes. You select other designs you like, colors, and styles of font and imagery. From your choices, Looka creates the perfect logo and layout for your brand.

Create Business Cards and Signage

Business cards, signs, posters, mailers, and everything in between help brand marketing campaigns, event booths, and even the exterior/interior of your machine shop. Vistaprint is a one-stop shop for all these things.

Like Looka, Vistaprint offers design options based on your personal preferences. Choose the font, color, and design you want and Vistaprint gives a variety of styles and print options for your machine shop marketing materials.

Purchase a Domain Name

The domain name for your website is important. Anything too vague and customers don’t know it’s a machine shop. Anything too over the top and your company may appear unprofessional. The ideal domain name for a machine shop is the name of your brand followed by dot com.

Try Namecheap.com for domain names as low as $6 a year.

Build a Website

Machine shops are an in-person brick-and-mortar business model. Even so, a website is a must-have to stay relevant, increase brand recognition, and engage with customers.

A website is like a digital storefront. It offers potential new customers an idea of who you are and what you do. It also helps them navigate service options and find contact information.

Not all machine shop owners are well-versed in web design. Fortunately, there are plenty of places to find experienced professional web designers that won’t break the bank. Fiverr is a good place to start. It’s a freelancer platform where you can find web designers looking for work, or post your own ad and accept bids on the project.

12. Join Associations and Groups

Joining machine shop business associations provides a place to gain advice, ask questions, and even source equipment. Some associations to watch for include National Tooling and Machining Association and Precisioned Machined Products Association.

Local Associations

Along with international associations, there are local associations to look for. Sometimes local associations incorporate other business types within your industry. This is useful for finding new clients, or partnering with teams that will later benefit your brand. For example, as a machine shop, you might find it useful to partner with a parts or hardware manufacturer. Getting discounts on tools and supplies is extremely beneficial in the competitive world of machines.

Find local associations by searching, “Machine shop associations in,” and adding your city and state.

Local Meetups

Meeting with machine shop groups and organizations offers valuable resources. Tradeshows and conferences are one place to get in touch with machine shop owners and upper-level management. You can also use digital resources like Meetup.

Meetup lets you find, or create your own, event or group. Search by city, zip code, event type, and industry to find the right meetup for you and your team.

Facebook Groups

Facebook groups are often left an untapped resource when starting a new business. As you start your machine shop, think about the networks you build and the people you connect with. Facebook groups are a great place to meet like-minded individuals on the path to successful machine shops.

Facebook groups are valuable because they cost nothing to joint. You can access information and connections within your industry locally or globally. You can also start your own Facebook machine shop business group if you aren’t getting what you want from existing groups.

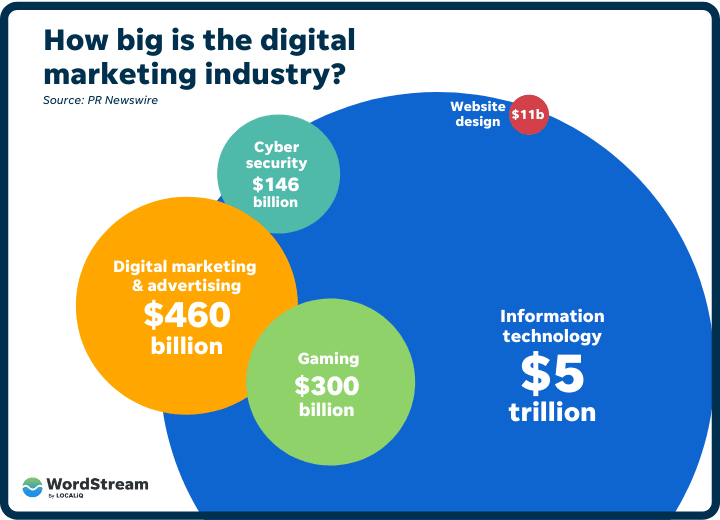

13. Focus on Marketing

Marketing your machine shop business is a necessary step in getting started. Niche businesses in the industrial sector, like this one, need to make themselves noticed. Things like search engine optimization and direct mail flyers help increase brand recognition among locals.

Here are some of the ways to begin marketing your machine shop in town.

Ask Friends, Family, and Coworkers

Word-of-mouth marketing makes an impact on consumers, especially business owners. If you have friends or family members in industries supported by machine shops, ask them to spread the word about your new business.

Your loved ones can help get your machine shop off the ground in several ways.

- Hand out business cards

- Tell locals about the business

- Visit the website and leave a review

- Rate the business on Google Businesses and other online business listings

- Put up flyers in the community

According to Forbes, 90% of consumers are more likely to buy or use a service based on a recommendation. This stands true even if the recommendation comes from someone they don’t know. It’s more impactful when the recommendation comes from a trusted source.

Digital Marketing Ideas

Digital marketing has become an integral part of any successful business strategy. As a new machine shop just starting out, digital marketing engages customers and spreads brand awareness.

Some forms of digital marketing are:

- Email campaigns

- Blog posts

- Google ads

- Facebook ads

- Social media posts

- Video uploads (TikTok and YouTube)

- QR codes and backlinks

- Newsletters

- SEO (search engine optimization)

Your website is also a big part of any digital marketing campaign. Ads, QR codes, and even social media posts should lead customers to your website to obtain services. The more traffic your site gets the better your chances are of a return on investment (ROI).

Traditional Marketing Ideas

Marketing your machine shop takes more than savvy Google ads and blog updates. While the machine shop industry is constantly evolving, there’s a strong sense of traditionalism among laborers and technicians. This calls for traditional marketing methods to spread the word throughout local industrial circles.

There are many forms of traditional advertising to choose from. Anything with a tangible visual impact does the job. Some classic forms of traditional marketing include:

- Business cards

- Direct mail brochures

- Bus and bench signs

- Billboards

- Television commercials

- Newspaper ads

- Community center bulletin flyers

You can also market your machine shop with commercial vehicles sporting logos and business names.

14. Focus on the Customer

Without customers, a machine shop is just a warehouse full of equipment and the experts who use them. Finding ways to show clients they matter to you promotes your brand above local competitors.

Machine shop clients are generally business owners within the industrial sector. Create customer focus by:

- Creating exclusive services and discounts

- Posting relevant DIY and “How To” videos to social media

- Connecting with industry leaders through networking events

- Offering loyalty and referral rewards

- Having tools and parts on hand for clients within niche industrial environments

Developing lasting client relationships is easier when you are an authority in your field. Show customers, you’re the right team for the job by knowing your products and services inside and out.

Hopefully, this guide has been helpful in learning to start your own machine shop. From branding and registering your EIN to engaging with customers, there’s a large market for successful machine shops. Best of luck as you get started with yours!